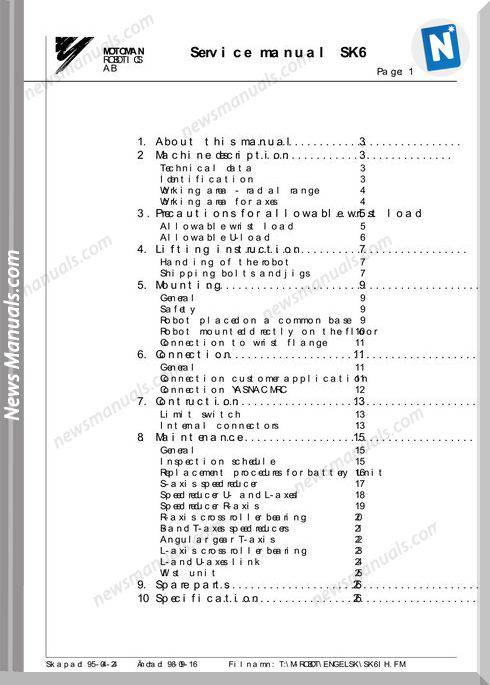

Related Manuals for YASKAWA Motoman Series. Controller YASKAWA MOTOMAN Series Instructions Manual 53 pages. Cc-link ie field communications function. Controller YASKAWA. Motoman Sk6 Service Manual Information Motoman Sk6 Service Manual This handbook has 733482 bytes with 50 pages presented to you in PDF format Page size: 595 x 842 pts (A4) (rotated 0 degrees). Motoman Sk6 Service Manual pdf manufactured by the company MAN presented for you in electronic format Page size 595 x 842 pts (A4) (rotated 0 degrees). This manual can be viewed on any computer, as well as zoomed and printed, makes it easy to diagnose and repair problems with your machines electrical system.

Keywords

Citation

(1998), 'Node welding robot', Industrial Robot, Vol. 25 No. 3. https://doi.org/10.1108/ir.1998.04925caf.008

Download as .RISMotoman Sk6 Manual Online

Publisher

:Emerald Group Publishing Limited

Copyright © 1998, MCB UP Limited

Node welding robot

Node welding robot

Motoman Sk6 Manual

Keywords Motoman,Robots, Steel, Welding

A Motoman robotic weldingcell, the third to be installed by the Karlskrona shipyard (Sweden), iscurrently being used in the fabrication of steel nodes required in theconstruction of the Oresund bridge linking Malmo (Sweden with Copenhagen(Denmark).

The cell, which has cutmanual welding times for the nodes by up to 50 per cent, comprises an XYZ gantrymounted Motoman SK6 welding robot interfaced with an especially developed 20tonne capacity manipulator. Programming is via a state-of-the-art Yasnac MRC32-bit microprocessor control.

The MOTOMAN XYZ gantry robot welding system used in the welding ofsteel nodes for the Oresund Bridge linking Sweden with Denmark

Motoman Sk6 Manual Download

To optimise up-time, useis also made of Motoman's ROTSY offline software which enables programming andproduction to run hand in hand.

Each node welded isapproximately seven meters long, weighs up to 20 tonne when completed, andrequires three passes through the robot cell.

According to Karlskrona'sproduction manager, Michael Tranberg, the use of robotic welding was dictated bya number of factors:

'We have 108 nodes toproduce. These are fabricated from steel sheet varying in thickness from 12 to30mm, depending on final placement. In the welding process, we will deposit some330 tonne of wire.

'If we relied on manualwelding it would take far too long. A skilled worker, for instance, can meltabout 2.5kg wire/hr. With the Moroman SK6, using rapid arc, we can deposit8-10kg wire/hr and improve weld consistency.

'Minimising hazards andmaking the job interesting is also important as we have high expectations withregard to quality.

'Operators, therefore, dotheir own programming. The MRC is extremely user friendly but to simplifyfurther and provide flexibility, we had a tailor made software system prepared.This is proving ideal.'

Construction of theOresund Bridge will take some 16,000 tonne of steel. The highest part is 1000mlong and consists of 54, 20m sections each of which weighs around 250 tonne.Each of the pylons holding the bridge is 240m high and the free heightunderneath is 60m.

For further informationcontact Robert Lewis, Sales and Projects Manager, Motoman Robotics (UK) Ltd.Tel: +44 (0) 1295 272755.

Comments are closed.